working principle of leeb hardness tester|leeb hardness tester manual : department Store 3.2 The LEEB test principle The basic principle is to use a rebound body of a specified weight, which is impacted on the test surface using a specified test force and then the impact velocity .

Resultado da S M L XL 2XL 3XL Width, in 17.99 20.00 22.01 24.02 25.98 27.99 Length, in 27.99 29.02 30.00 31.02 32.01 32.99 Sleeve length, in 8.90 9.17 9.45 9.72 10.00 10.39 Runs true to size Corre a su talla original - Hecha de Algodon suave This classic unisex jersey short sleeve tee fits like a well-loved .

{plog:ftitle_list}

WEBAssistir Séries Online sem travamento no Mega Series Online, o melhor site para assistir seriados online, atualizações diárias Series Online, Series Online Gratis, Series Completas, Series Gratis. Login to your account. Remember Me Register a new account Lost your password? LANÇAMENTOS.

Learn how the Leeb hardness tester provides quick and non-destructive material hardness assessments. Explore its working principles, benefits, and applications across .The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for testing sufficiently large workpieces (mainly above 1 kg). It measures the coefficient of restitution. It is a form of nondestructive testing. The Leeb hardness testing, otherwise called as Leeb Rebound Hardness Test (LRHT), is considered as one of the four commonly used . The core principle of the Leeb method revolves around measuring energy loss. During the test, an impact body strikes the metallic surface. The resulting loss of energy due to material deformation is .

Principle of Leeb Hardness Test. The principle of the Leeb Test depends on a combination of friction, elastic and plastic deformation. When a material is subjected to a tensile force, the .3.2 The LEEB test principle The basic principle is to use a rebound body of a specified weight, which is impacted on the test surface using a specified test force and then the impact velocity .Determination of the hardness of metallic materials according to Leeb is defined in the ISO 16859 and ASTM A956 standards. In this dynamic test method, the ratio of rebound velocity to impact velocity of a moving impactor is used to .• Press key to switch between hardness test and strength test. Only D and DC type of impact device has the function of strength testing. So hardness testing is the only selection if the impact device is not D or DC type. • Press key to print out the measured values after measurement. 2.4 Leeb Hardness Testing Principle

The HT-1000A and HT-2000A hardness testers operate on the Leeb principle, a dynamic hardness test method based on velocity measurement. They include a guide tube and an impact body. . Test work life: 40 hours continuous . The depth of the indenter is 0.01mm, which uses the Wechsler hardness unit (referenced as HW). The full range has only 20 graduations so a typical instrument is limited when testing metallic materials. 7. Leeb .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

Maximum Hardness of The Measured Work Piece: 940HV(for D,DC,DL,D+15,C impact device) Radius of Rurvature of The Measured Work: Rmin=50mm(If using Alien supporting ring, Rmin=10mm) . 2.5 Leeb Hardness Testing Principle The basic principle is: use an impact body of certain weight impacts against the testing surface under certain test .Thank you for your purchase of our Leeb Hardness Tester of TCM-R1 Series (it is called Hardness Tester below), the Hardness Tester is portable . Maximum Hardness of The Measured Work Piece: . 2.5 Leeb Hardness Testing Principle The basic principle is: use an impact body of certain weight impacts against the testing .The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test.

You can easily perform this test using a Leeb hardness tester. How Does it Work? The Leeb hardness test works by measuring the rebound velocity of a small, hard object that is fired at the material's surface. The device used for this test, known as a Leeb hardness tester, contains a spring-loaded impact body that strikes the material with a .QualiTip Plus is the latest cutting-edge Portable Rebound-type Leeb Hardness Tester, incorporating advanced micro-electronic technology and adhering to ASTM A956 standards for accuracy. . is built upon the Leeb Rebound principle. This pocket-size portable leeb hardness tester is uniquely designed, complete with a carrying case, test block .II. Principle of Leeb Hardness Test. The principle of the Leeb Test depends on a combination of friction, elastic and plastic deformation. When a material is subjected to a tensile force, the deformation element (i.e., the carbide ball) glides against the material’s surface. At the same time, it tries to follow its original direction of motion.MH600 portable Leeb hardness tester, intelligent design can be quickly and easily for on-site testing of metal hardness. IP65 protection, . Working Principle. The basic principle is to use an impact body of certain weight impacts against the testing surface under certain test force, then measure the impacting velocity and the rebounding .

portable hardness tester for steel

To be sure that while releasing the triggering button, the work piece, the impact device and the impact body are all stable and the starting force coincides with the axis of the impact device. 1 1 1 1 1 4.6 Measuring Procedure Use standard test block to check your hardness tester prior to a hardness test. (1)Loading The Leeb hardness test (LHT with test value of L D), introduced in 1975 by Dietmar Leeb (Leeb 1979), is a portable hardness tester, developed originally for measuring the strength of metallic materials, that has been adapted for prediction of σ c of rock (Kompatscher 2004).The LHT device, sometimes also referred to in the literature as the Equotip, is shown in . Minimum of four intervals shall be measured in each working range. . It is the same in the principle of the conventional hardness tests such as Brinell, Rockwell, Vickers, and Knoop. . (2015) Metallic materials — Leeb hardness test — Part 3: Calibration of reference blocks. Google Scholar ISO 376 (2011) Metallic materials .The Leeb hardness test is a dynamic test method and has the following characteristics:. It is one of the standardized methods (ISO 16859, ASTM A956).Depending on the method, the impact velocity is between 1.4-3.0 m/s. It .

The Leeb rebound hardness test method was developed in year 1975 by Leeb and Brandestini at Proceq SA to provide a portable hardness test for metals. It was developed as an alternative to the unwieldy and sometimes intricate traditional hardness measuring equipment. The first Leeb rebound product on the market was named “Equotip”, a phrase which still is used .

Dual value display, shows both Leeb and converted hardness L ar ge CDd isp lyw thb ck Can choose large font display and statistics display Automatically calculate maximum, minimum and average value . Hardness test block D (HDT-B-HLD3) is for* all other impact devices * * POPULAR MODEL main unit: 2xAA batteries

In conclusion, getting the accurate hardness value for material using the Rockwell hardness value is highly dependent on understanding the working principle of this test method. Knowing its part, which includes the indenter types, the scales, and applicable loads, will help you identify its most suitable application. In this video, you will get an overview of the full-featured UNI-T UT347A Leeb Hardness Tester.The UNI-T UT347A is a highly accurate and portable Leeb Hardne.

The Equotip 550 metal hardness tester is a versatile portable hardness testing solution using the Leeb rebound technique invented by Proceq. Top. Workspace EN English; Deutsch . - Work tool steel - Stainless steel - High alloy steel (Leeb D only: P/T91-92, 20Cr13, GH4145, C422, 630 grade, 616 grade)Leeb Hardness Tester Le eb1 2 0. Functions & Features: l English m enu, convenient and easy for operation.. l Hardness standards HL,HRB,HRC,HB,HV,HS can be used, free conversion between different standards. l Can calibrate HL,HRC,HB.. l On the basis of Leeb hardness measurement principle, can be used to detect a variety of metal materials for a ccurate and .

ETIPD Leeb Hardness Testing. Mikrometry hardness tester ETIPD is a kind of portable measuring tool; the leeb tester can be quick, nondestructive, and high accuracy when measuring common metal materials hardness. The Leeb hardness tester can be used in the laboratory, as well as the on-site engineering field.

Leeb Hardness Tester leeb130. Functions & Features: l English m enu, convenient and easy for operation.. l Hardness standards HL,HRB,HRC,HB,HV,HS can be used, free conversion between different standards. l Can calibrate HL,HRC,HB.. l On the basis of Leeb hardness measurement principle, can be used to detect a variety of metal materials for a ccurate and stab le .

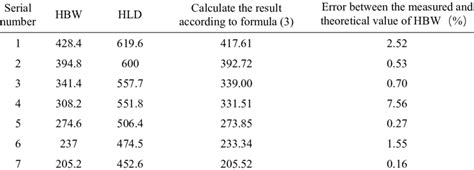

Leeb Hardness Tester leeb160/170. Functions & Features: l English m enu, convenient and easy for operation.. l Hardness standards HL,HRB,HRC,HB,HV,HS can be used, free conversion between different standards. l Can calibrate HL,HRC,HB.. l On the basis of Leeb hardness measurement principle, can be used to detect a variety of metal materials for a ccurate and .2.1. Analysis of the working principle of the Leeb hardness tester Figure 1 shows the measurement principle of the hammerhead of the Leeb hardness tester, and the calculation method is as follows: HL=1000× (VB/VA). where HL stands for the Leeb hardness value; VB stands for impactor rebound velocity; VA stands for Impact Body Impact Velocity.AND TEST PROCEDURE FOR LEEB HARDNESS TEST 6. Apparatus 6.1 The instrument used for Leeb hardness testing consists of (1) an impact device that is equipped with a spherically shaped tungsten carbide, silicon nitride, or synthetic diamond tipped impact body, an induction coil velocity measuring assembly, and a support ring, and (2) an electronic .

MH32 0 portable Leeb hardness tester is based on Leeb hardness measurement principle, it can be quickly and easily used for on-site testing hardness of metal lic . Ni-MH rechargeable battery is special made for MH500 / MH310 portable leeb hardness tester. With 6V working voltage, it can continuous work over 200 hours.Support repeated charging .

сверхвысокочастотные влагомеры

portable hardness tester for metals

Recuperar Senha. Usuário. Email

working principle of leeb hardness tester|leeb hardness tester manual